GRAVITY GOODS ROPEWAY

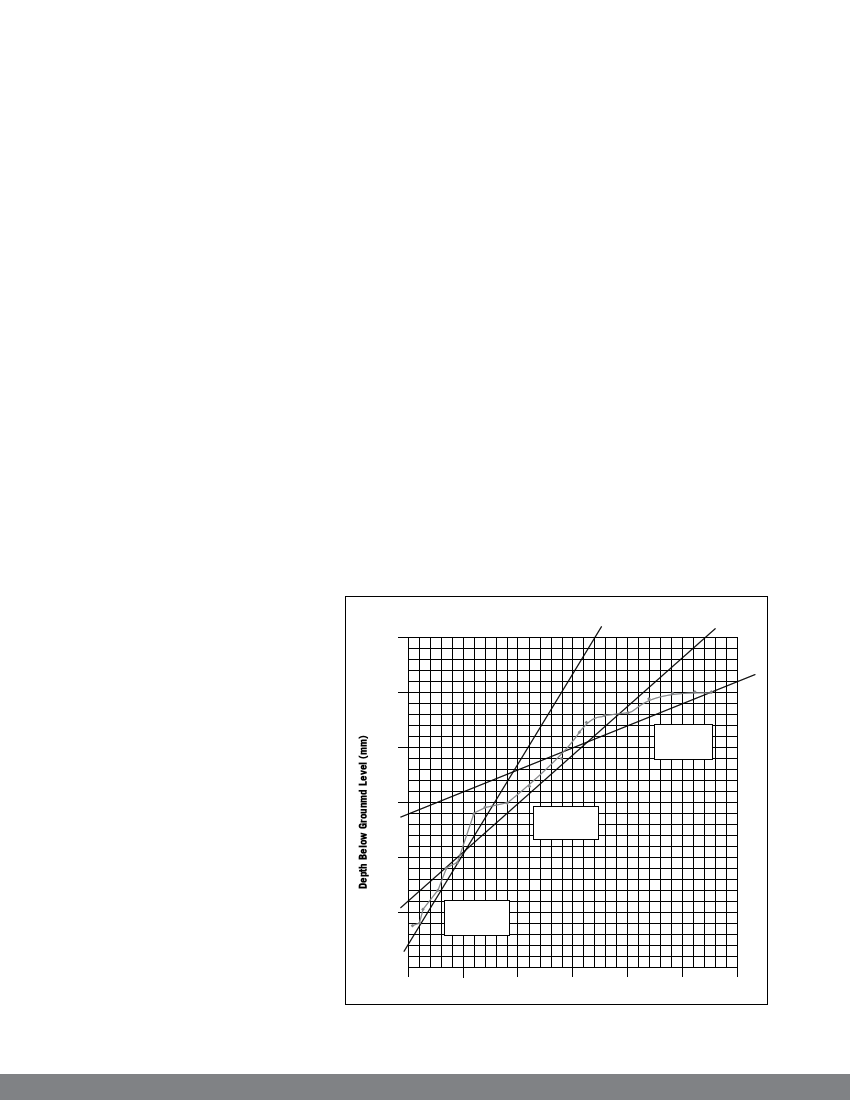

In general, a DCP penetration of 8 to 10 mm

per blow gives adequate founding ground. If

the soil strength is still very low at depths

greater than three metres, then the foundation

should be treated as poor soil. The empirical

relationship between DCP penetration and

equivalent ground bearing capacity are given

in figure 13.

With loose sands and silts, there is a great

danger of the excavation site collapsing,

especially if there is a flow of underground

water. The sides of the excavations should

be braced with timber to avoid the soil from

collapsing into the water. The investigating

engineer should design a suitable and safe

shoring method on the site.

If the water table is high and there is

a continuous inflow of water into the

excavations, the water should be pumped out

using ordinary buckets tied strongly by ropes

manually or through mechanised pumps.

The visual assessment by the investigating

engineer will determine whether disturbed

soil sample needs to be recovered

from the field for further testing

in the laboratory.

3000

laboratory tests of the soil samples. The soil

sample should be tested according to the relevant

code of practice. The laboratory tests will include,

following:

Particle size distribution: This test includes

wet and dry sieve analysis method combined

with the hydrometer analysis for the clay

fraction. The grading envelope will be plotted

from these tests. The coarseness and fineness

index, and clay fraction will be determined

from the particle size distribution test.

Plasticity index test: The liquid and plastic

limit test is carried out to find the plasticity

index.

Free swell test: This test determines the free

swell of the clay samples.

The criteria for potentially active clay is checked

from the above tests. If the soil is expansive, it is

highly recommended to change and relocate the

site for the stations or extensive sub soil treatment

may be required.

Penetration Chart

From the pit, following information

can be collected:

Ground strength

Soil type

Soil graduation

Compactness

Grain shape

Estimation of percentage of

boulder greater than 60 mm

diameter in soil

Ground water condition

Geological domination

2.3.2 Laboratory test

In cases where, on site visual

assessments have shown potentially

active subsoil, the soil activity should

be assessed further by carrying out

2500

2000

1500

1000

500

n=11mm/blow

dp==210.40-k2p.2a m

n=19mm/blow

dp==102.02-k1p.4a m

0 50

Figure 13: Penetration chart

100 150 200

Cummulative Blows

n=3mm/blow

pd=>426.02kmpa

250

300

14